Flexible mowing fleet meets contractor needs

Plain mowers boost work rates and need less power, but mower conditioners mean less time spent drying the crop, Jane Carley from Farmer's Guardian talks to a contractor who makes use of both designs.

Aiming to get the best of both worlds and to maximise tractor use throughout the rest of the year, one North Yorkshire contractor makes use of two types of mowing system; mower conditioner and plain cut.

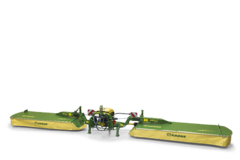

Based near Skipton, North Yorkshire, A.J. Long Contractors operates two tractor-mounted triple units; a Claas Disco 9200 Contour and a 9.7m Krone EC B 970, both specified as plain mowers.

Owner, Andrew Long says; "If fitted with conditioner units, the horsepower needed to drive the triple mowers would be a lot higher which would require larger tractors than we could find uses for outside of the silage season."

The plain mowers are driven by a 240hp Fendt 724 and 232hp Claas Axion 850, which can be used for a range of jobs year round, says Mr Long. He adds he did trial a 500hp tractor with a triple mowing outfit, but found that it lacked the necessary manoeuvrability.

In 2015, Mr Long added a 423hp Krone BiG M 420 self propelled mower conditioner with 9.7m cut to the fleet, to give additional mowing capacity while still working within the constraints of this traditional farming area.

Compact

"Many of the fields are just six or seven acres and then we have to travel a mile down the road to the next one," he explains. "So as well as having capacity, mowing units have to fold up neatly and be compact enough to go down narrow lanes and through tight gateways."

"A particular benefit of having a self-propelled mower is that it frees up a tractor for other jobs. The mowing unit is always ready to go and there is no need to take the mower beds off and put them back on again."

Making use of the BiG M's conditioning units speeds up drying time, taking dry matter levels up in less hours and keeping the mowing team ahead of the firm's three Claas Jaguar forage harvesters and a Krone BiG Pack large square baler.

"We will obviously use more fuel with a mower conditioner, but then it is doing an extra job and there is the benefit of fuel saving from the extra passes needed to dry the crop after cutting with a plain mower. In heavy crops, we would need two or three passes with the tedder after a plain mower and perhaps just one after using a mower conditioner."

Outputs vary widely depending on field size and Mr Long suggests while he is achieving 60 hectares (150 acres) per day in mainly small fields and heavy crops, in large fields the BiG M would cover 100 hectares (247 acres) per day comfortably. Work rates for the two systems are broadly similar given the lower horsepower of the tractors powering the triple mowers.

He says while the BiG M is straightforward to drive and any competent member of a foraging team should be able to handle it, he aims to keep one driver to each outfit.

"When an operator is familiar with a machine he can get the best out of it and look after it well."

Rare sight

With the BiG m still a relatively rare sight in the UK, a clued up operator has undoubted benefits in a busy season, although Krone UK is close at hand for back up and parts support.

Mr Long says he plans to get five years work out of the BiG M initially and then decide whether to trade it in for a newer model or fit new mower beds for another five years.

"We are still getting to know the strengths of the Krone mower bed design. The triple mower was new in 2013 and needed to be modified to follow the contours of some of the rougher ground in the area, so we have really only had two seasons experience of it. We hope it will outlast some of the other designs we have tried and expects mowers to last three to five years without any problems."

Article by Farmers Guardian

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)