-

Products

-

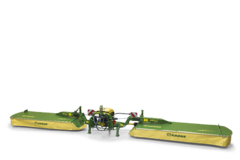

Disc Mowers

Disc Mowers

-

Rotary tedders

Rotary tedders

-

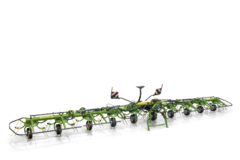

Rotary rakes

Rotary rakes

-

Round balers

Round balers

-

Bellima

Fixed bale chamber

Bellima

Fixed bale chamber

-

Comprima

Fixed, semi-variable or variable bale chamber – and baler wrapper combination

Comprima

Fixed, semi-variable or variable bale chamber – and baler wrapper combination

-

Comprima Plus

Semi-variable or variable bale chamber – and baler wrapper combination

Comprima Plus

Semi-variable or variable bale chamber – and baler wrapper combination

-

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png) VariPack

Fully variable bale chamber – specialist for dry crops

VariPack

Fully variable bale chamber – specialist for dry crops

-

VariPack Plus

Fully variable bale chamber – specialist for dry crops

VariPack Plus

Fully variable bale chamber – specialist for dry crops

-

-

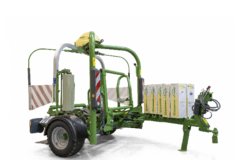

Bale wrappers

Bale wrappers

-

Large square balers

Large square balers

-

Pelleting press

Pelleting press

-

Forage wagons and trailers

Forage wagons and trailers

-

AX

Self-loading and forager-filled forage wagons – 25 to 31 m³

AX

Self-loading and forager-filled forage wagons – 25 to 31 m³

-

MX

Self-loading and forager-filled forage wagons – 33 to 40 m³

MX

Self-loading and forager-filled forage wagons – 33 to 40 m³

-

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png) RX

Self-loading and forager-filled forage wagons – 33 to 40 m³

RX

Self-loading and forager-filled forage wagons – 33 to 40 m³

-

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png) ZX

Self-loading and forager-filled forage wagons – 43 to 56 m³

ZX

Self-loading and forager-filled forage wagons – 43 to 56 m³

-

TX

Silage trailers – 46 or 56 m³

TX

Silage trailers – 46 or 56 m³

-

GX

General-purpose wagon – 44 or 52 m³

GX

General-purpose wagon – 44 or 52 m³

-

-

Mower conditioner

Mower conditioner

-

Forage harvesters

Forage harvesters

-

KRONE Digital

KRONE Digital

-

KRONE excellent Parts

KRONE excellent Parts

-

KRONE Crop Packaging

KRONE Crop Packaging

-

Finance

Finance

-

Please choose your language or country site

| International Maschinenfabrik Bernard Krone GmbH & Co. KG | DE EN FR ES RU CZ IT NL | |

| United Kingdom KRONE UK Ltd. | EN | |

| North America KRONE NA, Inc. | EN | |

| France KRONE France SAS | FR | |

| Russia OOO «КРОНЕ Русь» | RU |

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)