- EasyCut B 870 and B 1000 without conditioner

- EasyCut B 750, B 890, B 970 without conditioner

- EasyCut B 950 Collect without conditioner, with merger augers

- EasyCut B 870 CV and B 1000 CV with steel tine conditioner

- EasyCut B 870 CV Collect, B 1000 CV Collect

- KRONE quick-change blades

- KRONE SafeCut: Individually protected discs

- KRONE SmartCut: Stripe-free cutting

- KRONE CombiFloat: Uniform ground pressure across the entire work width

- Operator comfort to the max

Product video

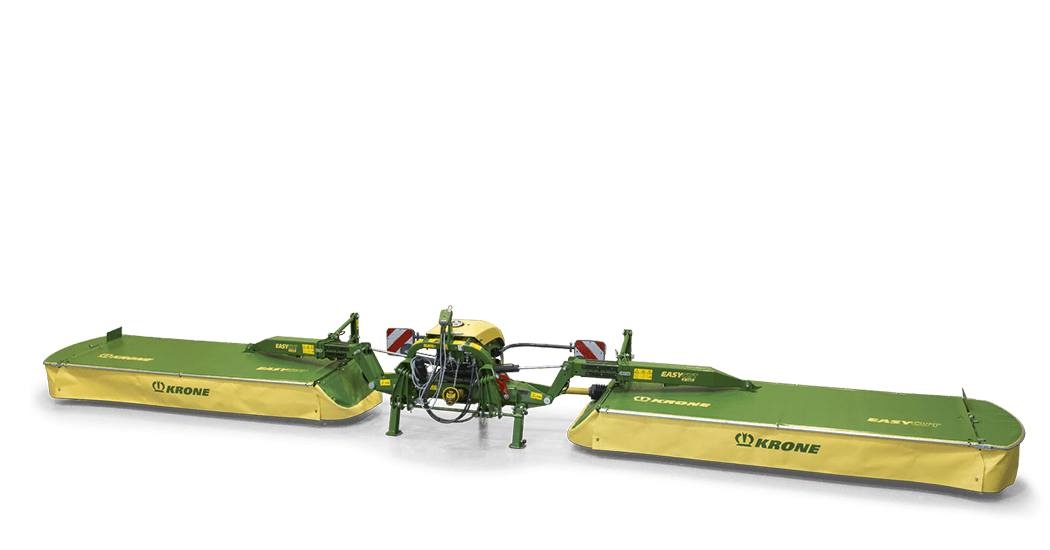

EasyCut B – KRONE mower combinations

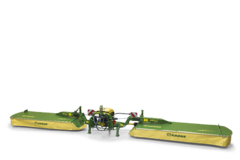

Introducing the new EasyCut B 870 and EasyCut B 1000, KRONE adds two models to its range of butterfly combinations. Compared with the previous butterfly mowers without conditioners, the new models stand out for a modern design and curved styling, taut curtains and an optimised weight thanks to a new headstock.

Product features

- KRONE SmartCut: Stripe-free cutting

- KRONE quick-change blades

- KRONE SafeCut: Individually protected cutting discs

- EasyCut B 870 and B 1000 without conditioner

- EasyCut B 950 Collect without conditioner, with auger conveyors

- EasyCut B 880 and B 1050 CV/CR Collect

- EasyCut B 1050 CV: With BiG Swath System

- KRONE Combi Float: Uniform bearing pressure across the entire work width

- EasyCut B 870 CV/CR and B 1000 CV/CR Collect

With innovative technology and excellent performance, the EasyCut B mowers set new standards in terms of efficiency. Whether dense grass, high field forage or difficult meadows – the EasyCut B models are up to every challenge. They perfectly adapt to the ground conditions and reliable follow the contour. The result: Even cuts without any compromise.

- Fully welded cutterbar: Robust, sealed and permanently lubricated

- Durable satellite drive with large spur wheels: Very quiet running and optimum power transmission

- Without inner shoe for trouble-free mowing

The completely welded cutterbar meets the highest quality standards, will remain leaktight and retain its shape even after long-term use. The large, oil-immersed spur wheels withstand sustained peak loads and are particularly quiet during operation.

- The wedge-shaped cutterbar guarantees clean cuts

- Heavy-duty spur gears run in double bearings

- Widely spaced bearings

- Swathing or wide spreading depending on needs

The wedge-shaped cutterbar offers great flexibility to adjust through a large range of settings and leave a short stubble in meadows and pastures as well as long stubble in long-stemmed forage crops. An EasyCut mower delivers a reliable performance and clean cut.

- Quick-change blades are standard specification, allowing operators to swap blades in the field quickly

- Modular disc design

- Minimum blade wear: 360° blade Action

- Excellent cuts from SmartCut: Optimum blade overlap

There are many reasons for choosing an EasyCut disc mower. Just think of the quick-change blades, the inexpensive wear parts and the perfect disc arrangement for stripeless cuts.

- Fully protected drives for greater reliability

- No collision with neighbouring cutting discs

- Wear-free

- Quick-change roll pins for minimum downtime and costs

Colliding discs may cause damage and involve costly repairs. KRONE SafeCut offers maximum protection. The award winning system on all EasyCut models offers a unique level of protection and operator comfort. SafeCut is part of the basic equipment of all EasyCut F series disc mowers.

- Patented DuoGrip attachment of the cutterbar: Mounted in the centre of gravity and controlled by parallel arms

- Uniform bearing pressure across the entire work width

- Optimum guidance: Less side pull, clean cuts

- Continuous suspension for superb contouring and sward protection

The KRONE DuoGrip suspends the EasyCut mowers in their centre of gravity and guides them with suspension arms. This design allows the cutterbar to follow the ground contours even more accurately for a better protection of the sward. and high-quality forage even in difficult conditions.

- V-shaped steel tines at steep angles give intensive and perfect conditioning

- The driveline dispenses with belts for frictional and low-maintenance Connections

- Great operator comfort from mechanical conditioner gearbox

- Adjustable baffle plates for enhanced conditioning

Efficiency is one parameter in hay and forage harvesting, quality is another. The high-performance KRONE CV conditioner with V-shaped steel tines spreads the crop at the full working width. The 640 mm diameter rotor and the helical arrangement of the tines warrant a continuous crop flow, high throughputs and superior conditioning.

- Variable swath width by means of optional accelerator rollers

- Tractor-independent oil supply through on-board hydraulic system

- Automatic activation and deactivation of the cross conveyor belts

- Divided conditioner tray for loss-free crop transfer

- Extra wide 910 mm cross conveyor belts handle large volumes of crop

The KRONE Collect system offers multiple setting options suitable for the most diverse applications around the world. The KRONE Collect cross conveyor belts deliver clean and perfect swaths that are easily picked up by the following harvesters for loss-free harvests.

The swath width of the EasyCut B CV and CR Collect can be preset by means of a hole pattern. The fine adjustment in keeping with the harvesting conditions is made via the belt speed and the optional accelerator rollers.

- Variable, up to 10.00 m work widths on EasyCut B 1000

- Weight-optimized headstock reduces rear axle weight and ground pressure.

- Adjustable non-stop impact damage protection system is a standard feature

- SmartCut and SafeCut ensure perfect cuts and maximum uptime

- Hydraulic suspension as a standard feature

In the EasyCut B 870 and B 1000, KRONE is presenting two powerful mower combinations that feature sophisticated technology and state-of-the-art design. With its optimised weight and hydraulic relief, the headstock not only protects the turf but also allows for use of smaller tractors.

- The outrigger arms adjust to two positions (EasyCut B 870) or infinitely variably (EasyCut B 1000) to provide optimum overlapping

- Optimum overlapping eliminates striping in curves and on slopes

- Hydraulic bearing pressure control conveniently from the cab

EasyCut B 870 and B 1000 are no-compromise machines. The infinitely variable arm length control adapts mower unit overlaps to the current conditions without compromising on acreage and output.

- Safe road travel thanks to 95° transport angle. Less than 4 m transport height and 3 m width.

- Compact storage position on sturdy support jacks

- LED lights and reflecting warning panels are standard specification

The carefully designed folding mechanism makes for a compact storage position. Road travel is safe, too thanks to the compact transport dimensions.

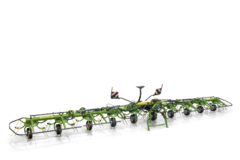

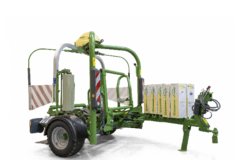

- Light-weight and compact mower combination without conditioners

- 9.45m working width including front mower

- Massive auger conveyors merge the swaths

- Three swathing modes are selected from the cab: individual swathing, partial width swathing and wide spreading

- Hydraulic mower suspension controlled from the cab

The EasyCut B 950 Collect is a very compact mower combination that has auger conveyors but no conditioners. The massive augers merge large volumes of crop such as green rye into a uniform and clean swath.

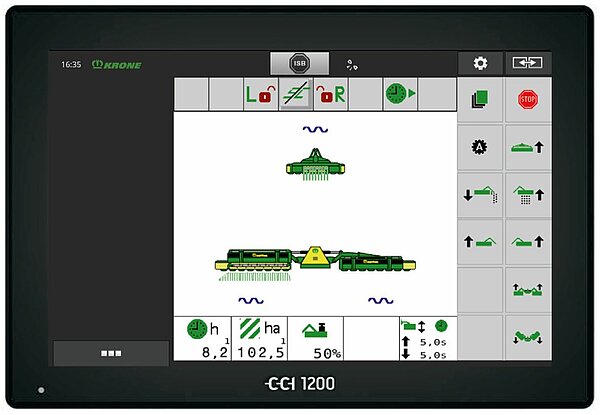

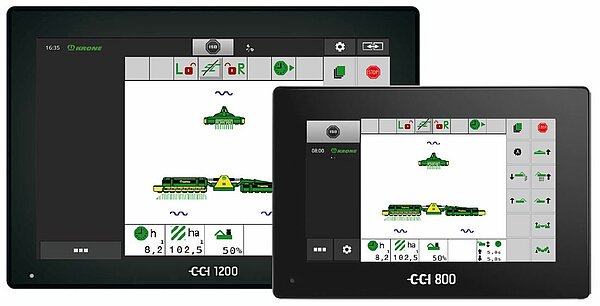

As an option, use the ISOBUS-capable Comfort control unit to operate the mower unit function via the tractor's terminals. The DS 500, CCI 800 or CCI 1200 with touch screen allow intuitive and covenient operation via Load Sensing.

In the EasyCut B 950 Collect, preselect the hydraulic functions via the PreSelect DS 50 or alternatively via the terminal using the PreSelect Digital. They will then be carried out by the tractor's control units.

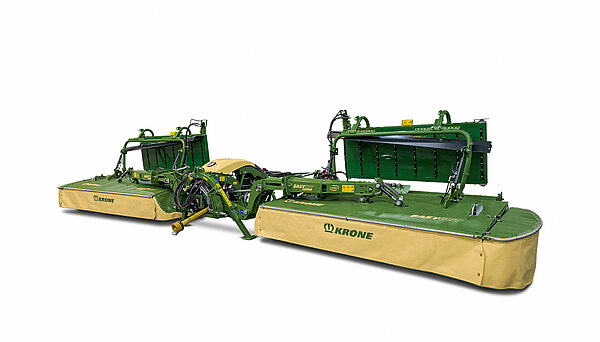

- 8.70 m work width

- EasyCut B 870 CV with tine conditioner

- EasyCut B 870 CR with roller conditioner (rubber rollers or M-Rolls)

- A compensation rocker ensures the bearing pressure is uniform on either side

- A standard impact damage protection system gives effective protection

EasyCut B 870 CV and CR not only utilise the power of your tractor but also save time and costs. The EasyCut B 870 with conditioners and extra wide cross conveyor belts has a versatile range of applications. This machine enables you to cut, condition and spread or swath the material in one single pass.

- High work rates from up to 10.10 m working widths

- EasyCut B 1000 CV with steel tine conditioner

- EasyCut B 1000 CR with an aggressive roller conditioner

- Hydro-pneumatic compensation for uniform ground pressures

- A standard break-back system gives effective protection

The EasyCut B 1000 CV and EasyCut B 1000 CR stand out for a huge 10.10 m work width and their powerful CV or CR conditioners. Another high-profile feature is the world-first Combi Float – the automatic and hydro-pneumatic control system.

- Hydraulic overlap adjustment

- Large setting range of up to 40cm per side

- Cleanest cuts in bends and on slopes

The standard hydraulic side shift feature on the rear mounted mower eliminates any striping and maximizes efficiency. Cutting straight lines, the machine operates at the maximum width and minimum overlap, whereas larger overlaps and a narrow working width is selected when cutting curves. As you operate on the slope, simply retrieve a stored sideshift range to the right or left and avoid drifting and striping.

- Convenient headland function by fingertip control

- Safe road travel: 4.00 m transport height and less than 3 m transport width

- Great operator comfort: Compact on the tractor, adjustable tractor-machine distance

- Minimum space requirement by storing in transport position

The side mowers are retract automatically so that the transport height of 4.00 m is not exceeded. An automatic transport locking system provides for safe road travel and is activated as the rear mowers are shifted to the middle.

- Extra wide cross conveyor belts for continuous flow even in high volumes of crop

- Each belts can be raised individually, providing one of the three swathing modes available: wide spreading, partial width swathing or single swathing

- Belts shut off and on automatically when raised and lowered

The Collect system with cross conveyor belts makes EasyCut B 870 CV and B 1000 CV with steel tine conditioners and EasyCut B 870 CR and B 1000 CR with roller conditioners versatile machines that spread the material across the working width or produce one central or two individual swaths. The powerful conveyor belts handle even the heaviest crops most effectively.

- Convenient for operators

- Clear concept

- Easy

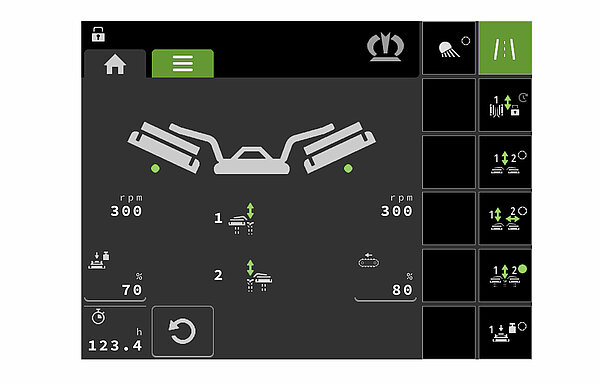

The Butterfly combinations EasyCut B 880 CV and CR Collect, B 950 Collect and B 1000 CV and CR (Collect) are available either with the electrical PreSelect operation or the ISOBUS Comfort control unit, which is the standard for the EasyCut B 1050 CV (Collect). The ISOBUS-compatible devices comprise a large choice of terminals and intuitive-use control units. SectionControl, the new CCI 1200/800 and the tried and tested AUX joystick CCI A3 are just two examples of what’s available.

The CCI A3 AUX joystick optimizes operator comfort and machine control. The pictorial function keys on the joystick’s touchscreen ensure that you always see what you are doing. The interchangeable frames allow the arrangement of the keypads to be optimally adjusted to the respective application.

With an 8” or 12" colour touchscreen, the CCI 800 and CCI 1200 operating terminals offer maximum user comfort. The screen displays one function at maximum zoom level and two further functions in a mini viewer, These terminals can also be combined with cameras, AUX joysticks and the licence for Section Control.

The EasyCut B 880 CV and CR Collect, B 950 Collect and B 1000 CV and CR Collect can be operated with the optional ISOBUS-capable Comfort control unit via the terminals in the tractor; the DS 500, CCI 800 or CCI 1200 with touchscreen feature intuitive and comfortable operation via Load Sensing. The EasyCut B 1050 CV (Collect) comes with a Comfort control unit as a standard.

With the help of KRONE PreSelect Digital, the preselection of the function and the operation of the control unit can be carried out via the AUX buttons of the ISOBUS-capable control lever of the tractor. Thus, all tractor and machine functions can be conveniently controlled via one joystick without changing the device.

Generally, the KRONE PreSelect Digital has the same functions as the KRONE PreSelect DS 50. The difference is that due to the cable link between the accessory equipment and the ISOBUS socket of the tractor, the view and preselection are performed on an ISOBUS terminal. Changing between the PreSelect DS 50 and PreSelect Digital is possible. PreSelect is available for B 870, B 1000, B 880 CV/CR (Collect) and B 950 Collect.

With KRONE PreSelect DS 50, hydraulic functions of the connected accessory devices are preselected and then actuated with the regulating valves on the tractor. Electrical functions such as the bearing pressure of the mowers are indicated directly and can be adjusted via keys. With power supplied via a 12V plug in the cabin, they are directly connected to the machine interface.

Models

| EasyCut B 870 | EasyCut B 1000 | EasyCut B 950 Collect | EasyCut B 870 CV | EasyCut B 870 CV Collect | EasyCut B 1000 CV | EasyCut B 1000 CV Collect | ||

|---|---|---|---|---|---|---|---|---|

| Working width (m) | 8.31 / 8.62 | 9.28 / 10.10 | 9.45 | 8.70 | 8.70 | 9.30 / 10.10 | 9.30 / 10.10 |

configure

|

| Transport height at 250/200 mm ground clearance (m) | 3.60 | 4.00 | 4.00 | 3.80 | 3.80 | 4.00 | 4.00 |

configure

|

| No. of discs | 10 | 12 | 12 | 10 | 10 | 12 | 12 |

configure

|

| No. of top hats | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

configure

|

| Input power (kW/hp) | 88 / 120 | 100 / 140 | 145 / 200 | 110 / 150 | 125 / 170 | 130 / 180 | 145 / 200 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)