forage harvester BIG-X-480 Krone UK

BiG X 480, 530, 580 and 630 – the compact precision forage harvesters from KRONE for outputs of 490 hp to 653 hp and maximum chopping quality and output as well as superior ease of use and operator comfort.

- 490-653 hp continuous engine output

- 6 intake rollers for premium safety and a top quality chop

- MaxFlow chopping drums with 20, 28 or 36 blades, biogas drum with 40 blades

- KRONE VariQuick for ultra-quick changeover with or without grain conditioner

- OptiMaxx roller conditioners measuring 250 mm in diameter and 570 mm in width for intensive kernel processing

- KRONE VariLOC for flexible choice of long and short chops

- KRONE VariStream – spring-loaded plates beneath the chopping drum and at the crop accelerator ensure a continuous crop flow

- Convenient hoop coupler for easy attachment to the base machine

- Superb manoeuvrability from independent wheel suspension and wheel motors

- Optionally with four-wheel drive

- 3 m machine width (depending on tyres) for easy travel on public roads

The chopper unit

Optimum layer thickness

It's not just the number of blades that accounts for a good quality chop. The thickness of the mat that passes through them and therefore the width of the chopping drums are just as important. Therefore KRONE designed a wider 630 mm chopping drum for the BiG X 480, 530, 580 and 630 which carries the customary high chopping quality of the high-capacity foragers with 800 mm drums over to the smaller models.

Product features

BiG X 480, 530, 580 and 630 – the compact precision forage harvesters from KRONE for outputs of 490 hp to 653 hp and maximum chopping quality and output as well as superior ease of use and operator comfort.

- 6 intake rollers for maximum reliability and best chop quality

- MaxFlow chopping drums with 20, 28, 36 blades, biogas chopping drum 40 blades

- KRONE VariLOC: flexible use in long and short cut

- OptiMaxx roller conditioners with 250 mm diameter, 570 mm width and slanted teeth for intensive kernel conditioning

- KRONE VariQuick: quick changeover for working with and without corn conditioner

- KRONE VariStream: Continuous crop flow ensured by spring-loaded floors for chopping drum and discharge accelerator

- Powerful and low-emission engines from 490 to 653 hp

- Great manoeuvrability from independent wheel suspension: For extreme manoeuvrability

- Comfort cabin: For optimum overview and comfort at the workplace

BiG X 480, 530, 580 and 630 – the compact precision forage harvesters from KRONE for outputs of 490 hp to 653 hp and maximum chopping quality and output as well as superior ease of use and operator comfort.

- KRONE chopping technology for optimum maize forage quality

- OptiMaize S, M, L, XL for variable chopping lengths from 4 mm to 30 mm

- KRONE MaxFlow and biogas chopping drums with different numbers of blades for producing the cutting length you need

- KRONE grain conditioners ensure optimum fracturing and kernel treatment

- KRONE VariLOC for flexible long and short chops without converting the machine

OptiMaize brings full flexibility to all KRONE BiG X forage harvesters, allowing them to produce any type of cutting length forage producers call for. MaxFlow and Biogas drums are available with various numbers of blades and combine with the specific KRONE conditioners for chop lengths of 4 mm to 30 mm.

- Six intake rollers ensure a top-notch quality of chops

- High throughput with universal or biogas chopping drums

- OptiMaxx roller conditioner: Intensive conditioning

- VariStream: Continuous crop flow

- StreamControl: Optionally adjustable discharge distance

- VariQuick: Quick access to the grass channel or grain conditioner

When you’re looking to maximize throughputs with a top-quality chop, the technology must be up to the job. With the BiG X, KRONE offers a forage harvester which convinces by top cutting quality, highest throughput and maximum user comfort thanks to the direct crop flow and the numerous innovative details which meet the requirements of successful service providers and make the working day easier.

- 6 pre-compression rollers for top-quality chops

- Hydraulic drive

- Stepless adjustment of the chop length from the cab

- Automatic adjustment of the chop length via AutoScan or NIR sensor

- Maximum protection against foreign objects

- Long path from metal detector to chopping drum

- Metal detection across the entire channel width

On a BiG X, it is also the intake system that has an influence on the quality of chop. The six intake rollers compress the chopping crops consistently at a high pressure so that it is easier and more precisely to chop. The hydraulic drive of the intake system allows operators to choose between setting the cutting length manually or automatically.

- Chopping drums with 20, 28, 36 or 40-blades for OptiMaize S to XL

- High flywheel mass: Closed drums with a diameter of 660 mm

- Top chop quality: Drums with a width of 630 mm matched to BiG X 480, 530, 580 and 630

- Low fuel consumption: High flywheel mass, pulling cut

Matching the drum dimensions to the harvester model and choosing the optimum number and shape of blades not only boosts the power of the BiG X but also makes the OptiMaize S, M, L, and XL more flexible to suit more applications. The wide range of drums available for BiG X deliver a top-quality chop in any conditions anywhere in the world – at top performance levels.

- For grass, wilted crops, whole crop silage and maize in OptiMaize S, M, L, XL

- Chopping drums with 20, 28, or 36 blades

- Large conveyor space under the blade carriers

- Blades are quick and easy to insert and remove

The MaxFlow chopping drums are specially designed for conditioning of high-quality silage. Harvesting wilted crops with unevenly formed swaths is a challenge for the chopping drum; therefore, its blade supports have a special shape which leaves more room under the blades. Larger ‘pockets’ and the spring-loaded drum base result in extremely smooth running and high power reserves. So BiG X makes light work of temporary crop accumulations.

- 40 blades arranged in V-shape

- High frequency of cuts

- High productivity

- OptiMaize S

- High gas yields

With its 40 blades, the KRONE biogas drum chops the crops very thoroughly. OptiMaize S achieves very short chop lengths which enable high throughputs both on the machine and in the fermenter, making BiG X a major factor in biogas plant productivity.

- OptiMaize is a versatile and unique system

- Cutting length gearbox for flexible use in short and long cut applications

- Changeover of the drum speed is a matter of a few minutes

- No machine conversion, no up-front planning

VariLOC is a gearbox in the pulley of the chopping drum. By simply changing the drum speed from 1,250 to 800 rpm using a standard open-end wrench, you can increase the chopping drum’s LOC range by up to 50 %. This makes a quick changeover between long or short chops possible. You can fulfil your customers' fluctuating demands without any conversion or up-front planning. Combined with the new 105/123 tooth roller conditioner (with 30 %, 40 % or 50 % speed difference), this gearbox turns your BiG X into an all-rounder and gives you maximum flexibility.

Our roller conditioners redesigned

- 570 mm wide and 250 mm diameter OptiMaxx roller conditioners

- Slanted teeth for perfect conditioning to combine with OptiMaize S-XL drums

- BusaCLAD-Special coating technology for maximum service life

- The gap between the rollers is conveniently adjusted from the cab

- A strong spring assembly provides a consistent and high pressure

- Maximum fracturing from an up to 50% speed difference (option)

Every single kernel must be cracked to achieve an optimal digestibility. These user demands are perfectly met by the new OptiMaxx roller conditioners with their slanted teeth, a new KRONE development. The rollers score on a massive 250 mm diameter and a 570 mm width

- Fast changeovers from grass channel to corn conditioning and vice versa

- A chain drive lowers the unit conveniently

- The changeover takes just a few minutes

- Fast and easy removal of the grain conditioner

VariQuick is the system that allows operators to converse BiG X very quickly from maize to grass and the other way round. A chain drive (electric option) moves the corn conditioner out of or into the crop flow. If the corn conditioner is not used for longer periods of time, you can lower it and remove it from the machine by pulling it out to the side.

- Consistently smooth performance despite inconsistent crop flows

- Extremely quiet running even in uneven swaths

- High throughputs

- Top quality chop

- Perfect operator comfort

VariStream comprises spring-loaded floors beneath the chopping drum and behind the discharge accelerator rotor. The system ensures blockage-free and smooth operation, even in varying volumes of crop. The technology allows operators to utilise the forager to its limit and use less fuel per hour.

- Adjustable discharge distance from the cab as an option

- Tight crop stream even with a long crop discharge

- The shorter the crop discharge, the less power is needed

- Fills the transport wagon accurately without spillage

The crop throw is controlled from the cab by adjusting the flap in the rear wall on the discharge accelerator.This way, operators can adjust the throw quickly to the current filling situation. As the accelerator needs less power to cover a short distance, the operator can free up engine output and use it for chopping and higher throughputs.

- Convenient attachment and removal

- Maximum safety

- Very short set-up times

- Compact combination

The multi-coupler system of the BiG X allows operators to couple headers fast, easy and dependably from the seat, reducing changeover times when preparing for road travel or different crops.This way, more time is spent on productive work.

- More power, quieter running, less wear

- Infinite speed adjustment from the driver's seat

- Automatic pick-up speed adjustment to the current driving speed

- Quick coupler and coupling hoop make for quick header attachment and perfect contouring

- Six rows of tines in W-arrangement

The camless EasyFlow 300 S and 380 S pick-ups by KRONE have neither deflection rolls nor cam tracks. Compared with conventional pick-ups, EasyFlow has up to 58% fewer moving parts, which makes it impressively smooth running, low-wear and therefore inexpensive in service and maintenance. EasyFlow operates 30% faster for cleaner gathering and increased productivity.

- Direct cut headers with 6.20 m working width

- Heavy throughput, low power requirement

- KRONE EasyCut mower technology that is proven the world over

- KRONE SafeCut: unique protection for mower discs

- Powerful feed auger with replaceable HARDOX wear plates

Based on the well-proven KRONE EasyCut cutterbar technology, the XDisc direct cutting system allows the BiG X to cut and chop whole crop silage in one operation. which features SmartCut cutting performance and quality and SafeCut impact damage protection.

With its working width of 6.20 metres, the KRONE XDisc 620 direct cut header achieves a high acreage output and therefore efficient harvesting of whole crop silage.

- Variable-row maize headers with 6 m to 9 m working widths

- Best quality of chop, fewer overlength fractions from linear crop feed

- Simple technology and low input power

- The central gearbox

An extra running gear is available as an option for the two-piece EasyCollect model offering maximum road safety.

The variable-row EasyCollect header is a versatile unit that feeds the stalks lengthwise into the machine, which translates into an unsurpassed quality of chop, as a coarse chop is the last thing livestock farmers or biogas producers want. The unique collector principle cuts labour costs and has proved its worth time and again the world over.

- Available work widths are 6 m, 7.50 m and 9 m.

- Variable-row harvesting with rotating sickle discs

- Operates to the collector principle, splits the processes of cutting and feeding

- A smooth and soft cut eliminates vibrations and crop loss

- Operators adjust the cutting frequency infinitely variably to suit the prevailing harvest conditions

KRONE adds new XCollect headers to the long-standing and well-proven EasyCollect series. The XCollect headers split cutting and feeding into two separate processes, responding to customer demands to deal with diverse harvest conditions around the world.

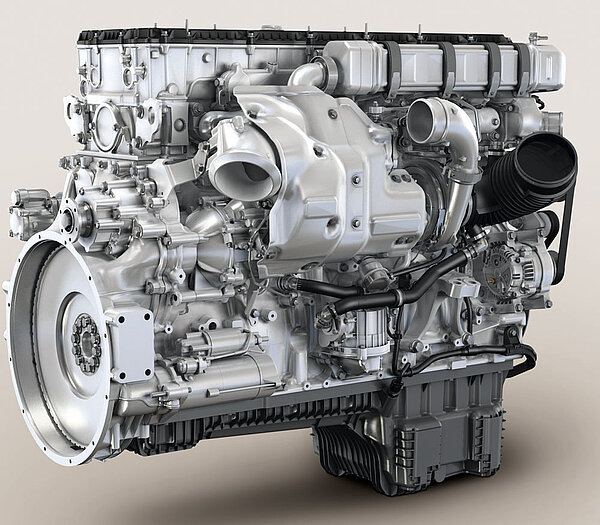

- 6-cylinder MTU in-line engine

- Final Tier 4 / Stage V compliant

- 490-653 hp continuous engine output

- High efficiency and quiet running

Cutting-edge technology from MTU takes engine power and economy to a new dimension. Common Rail injection and optimal torque synchronization translate into smooth running, low fuel consumption, high efficiency and minimal maintenance. The innovative KRONE power management guarantees highest efficiency with maximum throughput.

- Simple design

- An extra-strong poly V-belt transmits engine power to the crop assemblies

- Long service life

- Separate drive for the intake rollers and the headers: Rollers and headers are reversible if the chopping drum suddenly stops

- Separate and dependable driveline to the drive pumps

The transversely mounted engine allows the drive pump, the chopping drum, the crop accelerator, the header and intake pumps to take the engine power directly off poly V-belts. No power take-off gear is required. All components for crop flow are activated via belt coupling.

- Front-wheel drive is standard; four-wheel drive is an option

- Powerful wheel motors from Bosch-Rexroth

- Traction control with three travel modes

- Infinitely variable 0-40 km/h speed range

The hydrostatic wheel motors offer greater productivity and a higher level of automation and operator convenience. At the same time, this type of power train reduces maintenance and frees valuable space to fit a bigger and more powerful chopping assembly and move this further to the rear of the machine.

- LED lights are an option for best visibility at night

- Huge fuel capacity: up to 1450 litres of diesel with the optional additional tank

- Easy access for maintenance work

Long working days, sometimes even deep into the night, take a toll on the operator's endurance and concentration. This obviously requires excellent all-round visibility and full illumination at night, which is exactly what BiG X offers. The up to 1,450-litre fuel tanks hold enough diesel reduce the number of time-consuming top-ups and boost productivity Optimum access to all components ensures trouble-free service and maintenance.

- Plenty of space and optimum climate control

- Large window screens offer perfect all-round visibility

- Maximum seating and operator comfort throughout a long working day

- User-friendly operator terminal with colour-display touch screen

New premium cab developed to the latest ergonomic insights Providing generous space and an extra seat, it offers a fully air-conditioned and absolutely functional working place, where the operator feels at home and has full command of all functions and controls.

- AutoScan enables operators to adapt the chop length relative to the current degree of maturity of the crop

- ConstantPower ensures minimum diesel consumption at maximum throughput

- XtraPower increases engine power on demand

- EasyLoad supports operators in filling the harvest fleet trailers to capacity

- RockProtect protects the forager from damage by stones

KRONE offers a range of different systems which help utilise our BiG X forage harvesters to their full potential and ease the strain on the operator. The electronic assist systems supply relevant data on the crop and provide reliable Information in extremely difficult position.

Models

| BiG X 480 | BiG X 530 | BiG X 580 | BiG X 630 | ||

|---|---|---|---|---|---|

| Engine | MTU 6R 1300 | MTU 6R 1300 | MTU 6R 1500 | MTU 6R 1500 |

configure

|

| No. of cylinders | 6 | 6 | 6 | 6 |

configure

|

| Engine capacity (l) | 12.80 | 12.80 | 15.60 | 15.60 |

configure

|

| Continuous engine output (kw/hp) | 360 / 490 | 390 / 530 | 436 / 593 | 480 / 653 |

configure

|

| Max. Continuous X-Power chopping output (kW / hp) | 338 / 460 | 368 / 500 | 408 / 555 | 452 / 615 |

configure

|

| Max. Continuous Eco-Power chopping output (kW / hp) | - | - | 338 / 460 | 338 / 460 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

Flexible Finance Options Available

Investing in new machinery has never been easier. With Krone UK's tailored finance solutions, you can spread the cost to suit your budget and business needs. Discover our finance options here.

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/1/c/csm_VariPack_Freisteller_01_a70a02f9f9.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (UK):] [Translate to EN (UK):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN (UK):] Testname Forage harvesters - BiG X 480 · 530 · 580 · 630](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)